What’s rapid prototyping (RP)?

Rapid prototyping creates physical parts direct from the CAD model data. It uses different manufacturing techniques to achieve this task. You can use rapid prototyping for sub and main components at any development stage cycle.

Repeat prototyping several times alongside the new product design using test data. You will get your desired component.

Rapid prototype (RP) is a new term for creating prototypes quickly to functionally. RP visually evaluates the features of some parts. At times individual parts get made and assembled rapidly and separately to test a prototype.

What’s a prototype?

In engineering product design, prototypes are preliminary versions of end products to evaluate designs. They analyze working principles, test technology, and give the final product specifications. A prototype is an integrated engineering product design element in new product development.

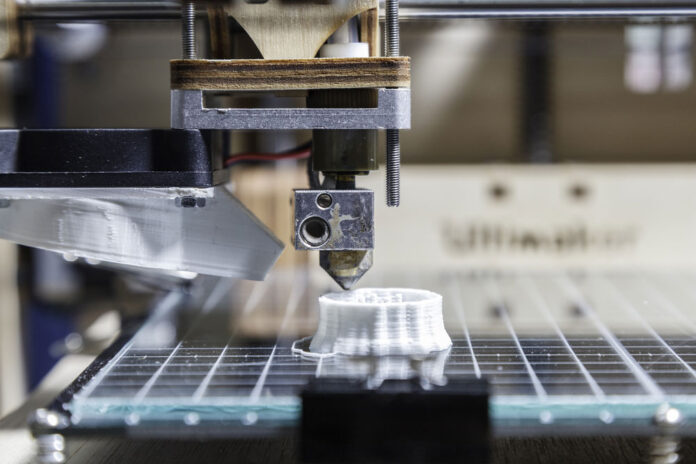

Is 3D printing the same as rapid prototyping?

No, RP is mainly used alongside other terms in the current product development. Such terms are additive manufacturing and 3D printing. The reason is that 3D printing was the first to exist to make prototypes faster.

The 3D rapid printing prototype cases

The additive manufacturing technology types have made giant strides in producing quality parts. It’s not the most preferred method since making some prototypes is expensive.

Additive manufacturing or 3D printing is a production process. On the other hand, rapid prototyping is the final product or result. 3D on its own can help you to make rapid prototyping.

The essence of rapid prototyping

Industries need to introduce and develop new products to manage the stiff competition. Technology innovation and faster product development are essential to a company’s success. RP is the most crucial aspect of developing new products.

Objectives achieved by rapid prototyping

The fast development of new products

Rapid prototyping has a significant role in building successful products. It speeds up the development process of the new product.

Early-stage concept/design validation of function, form, and fit of design

The end-stage of product verification against business needs and technical requirements

It permits functionality testing, checks the concept objectives, and finalizes product specifications.

Prototypes give client, end-user, customer, user participants the hands-on experience to receive feedback.

Applications of rapid prototyping

Concept models

Visual prototypes

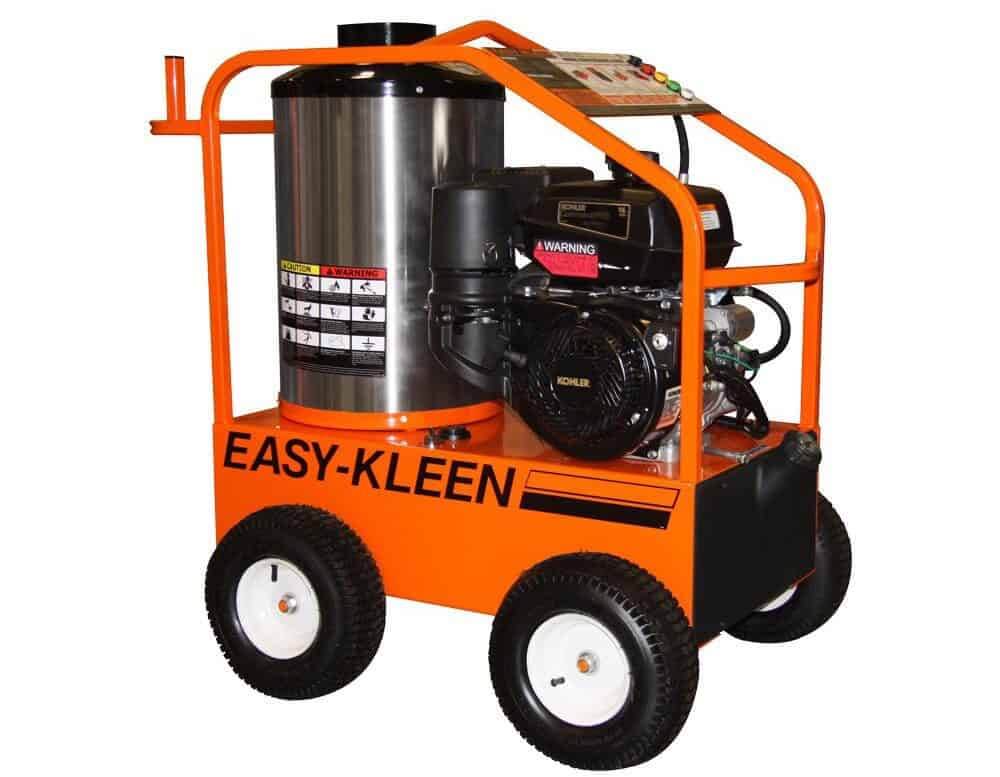

Functional prototypes

Production tools prototypes

Preproduction prototypes

Production molds prototypes

Types of RP

Rapid prototyping is for individual parts and not assemblies. You can categorize prototypes depending on the degree of:

Accuracy

Purpose

Product

Bluetooth dongle prototype

They are single-shell models to semi-functional RPs. Rapid prototypes don’t have to resemble the exact final product. They can vary depending on what the product designer wants to achieve. You can classify the prototypes depending on fidelity or accuracy. The degree of prototype accuracy varies from low to high fidelity in:

Appearance

Functionality

Size

User interface

Low fidelity prototypes get produced quickly and are very simple to test the bigger concept. Examples are paper sketches on cardboard mockups.

The high-fidelity prototype’s functions appear similar and close to the end product.

Conclusion

Since rapid prototyping is essential in production, you need to select the best fit one that you will use. You need to include rapid prototyping in your product design to create the best product.